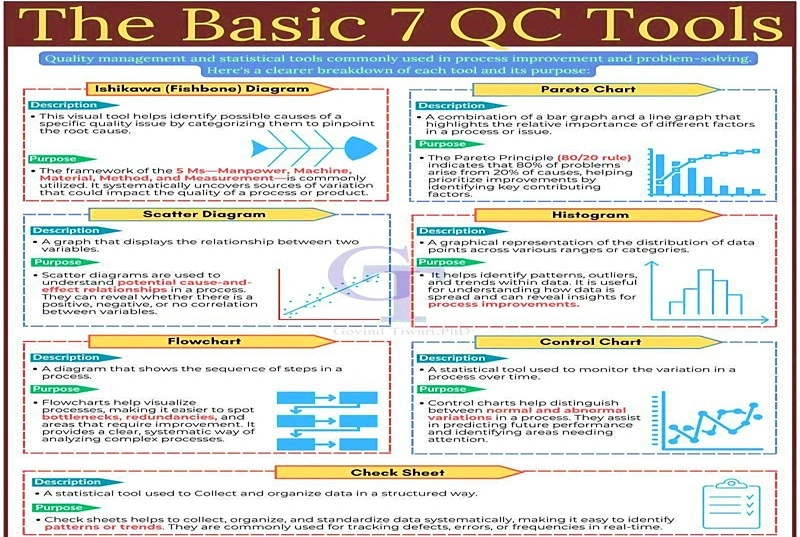

Quality professionals worldwide rely on tried-and-true tools to ensure process efficiency and problem-solving. The Basic Seven QC Tools, introduced by Kaoru Ishikawa, are fundamental techniques that empower teams to address issues systematically.

Here’s a quick guide to these tools, their purpose, uses, and benefits:

1. Fishbone Diagram (Cause-and-Effect Diagram)

Purpose: Identify potential causes of a problem and categorize them systematically.

Uses: Root cause analysis, brainstorming, and troubleshooting.

Benefits: Encourages team collaboration and helps visualize complex problems.

2. Pareto Chart

Purpose: Focus on the most significant factors contributing to a problem (80/20 rule).

Uses: Prioritize issues for resolution, analyze defects, or customer complaints.

Benefits: Highlights key areas to maximize improvement efforts efficiently.

3. Scatter Diagram

Purpose: Show relationships between two variables to identify correlations.

Uses: Analyzing cause-effect relationships, process improvements.

Benefits: Offers data-driven insights into trends and dependencies.

4. Histogram

Purpose: Visualize data distribution to understand variations.

Uses: Identify patterns, deviations, and trends in processes.

Benefits: Simplifies data interpretation for decision-making.

5. Flowchart

Purpose: Map processes step-by-step to identify inefficiencies or bottlenecks.

Uses: Process improvement, training, and communication.

Benefits: Enhances process transparency and promotes standardization.

6. Control Chart

Purpose: Monitor process stability and detect variations over time.

Uses: Statistical process control (SPC), quality monitoring.

Benefits: Prevents defects by identifying out-of-control conditions early.

7. Check Sheet

Purpose: Collect and organize data in a structured way.

Uses: Track defects, frequencies, or issues in real-time.

Benefits: Provides actionable data for analysis with minimal effort.

𝙒𝙝𝙮 𝙐𝙨𝙚 𝙏𝙝𝙚𝙨𝙚 𝙏𝙤𝙤𝙡𝙨?

• Simplicity: Easy to understand and implement.

• Versatility: Applicable across industries and processes.

• Effectiveness: Proven to improve problem-solving and quality.