Structural & Mechanical Equipment Inspection

Aramco QC Notes Level-14

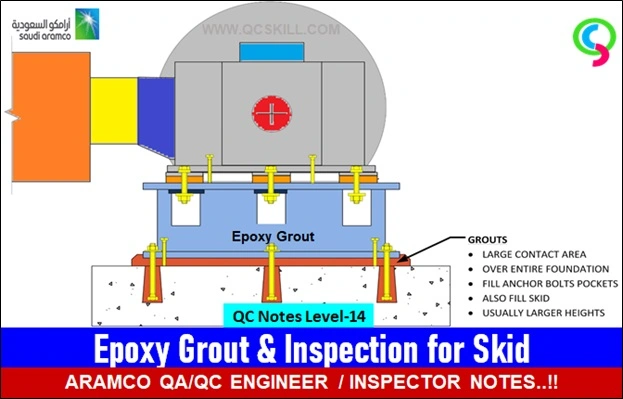

How to Place Epoxy Grout When the Skid Has no Grout Access Holes

The warning often seen during televisions commercials that only trained professional should attempt what is being demonstrated, also applies to skid grouting. Trained supervisors are available and well worth whatever extra it costs. Moving epoxy grout horizontally 12 feet over rough concrete that is 2 inches below the bottom the bottom is the difficult task. In years past when cement based grout were used (usually unsuccessful) for skid grouting, chains and steel banding were used to move the grout from one side to the other. Epoxy grout do not moved much with chains and a new technique has developed where the grout is pulled from one side to the other. Briefly the major steps are as follows:

- A head box is added to the wood forms on the side where the grouting starts.

- On the opposite side a 1 inch hole is drilled horizontally through the wood form

- A pulling tool head is placed inside the wood form and a piece of ¾” conduit, 3 feet longer than the skid is wide is screwed into the tool.

- Grout is poured into the head box and the pulling tool is pushed horizontally over to the other side until it is under the head box. As the tool is retracted two blades or wings deploy to form a tee. Pulling the tool away from the head box moves the grout from one side over the other. As the tool is pushed back again towards the head box, the wings retract so as not to move the grout back from where it came.

✅ JOBSITE RECEIVING AND INSPECTION

Upon arrival of the machinery or portion thereof at the job site:

- Visually inspect components for physical damage or contamination by opening crates or packages. Hermetically sealed containers should not be open, but visually inspected for damage and the hermseal maintained.

- Verify that shipping protection has been applied and still in effect.

- Verify that shop inspection has been completed and that the vendor has supplied the purchase order documentation and packing lists.

- Verify that loose components and separate packages match the packing list.

- Verify that special handling instruction are provided and carried out.

- Verify proper identification of the components.

- Perform visual inspection of the components for compliance with the project requirements.

- Inspect carbon steel and other ferrous flange faces damage and coat with type A, B, or D preservativunless prohibited by process application.

- Verify that plug and caps are in place, desiccants are unsaturated and equipment are lubricated as required. Non metallic (such as plastic) plugs and caps shall not be used.

- Verify that enert-gas-purged equipment still has the required pressure applied. Report failure to the manufacturer and request corrective action. This equipment shall remain sealed unless otherwise instructed by designated machinery representative.

- Inspect grout surfaces for proper factory blasting and coating.

- Tapped opening on the stuffing boxes and gland plates shall be closed and sealed with pipe plugs.

- Plug materials shall of the same or better than the sealed gland plate metallurgy. As a minimum, the plug shall be stainless steel.

- When specified, impact measuring devices shall be inspected to determine that the equipment has been exposed to excessive shock loads. Where required the manufacturing representative shall be present.

- Record all the inspection results.

✅ BASE PLATE INSTALLATION AND LEVELING (API 610 and ASME Pump)

- All base plate elevations shall be set in accordance with the construction drawings

- Prior to grouting, an initial alignment check in accordance with the alignment section of this document shall be performed to verify that coupling spacing and final alignment can be achieved without modifying the hold down bolt or the machine feet

- As minimum, base plate level shall be set with a master level or a precision machinist’s level. Level should be checked before beginning the plate.

Continue QC Notes Level-15 ⭕ Coating and Painting SAES-H-100; APCS-5A/B

See More: Aramco Quality Standard