Introduction:

It is the branch of engineering which deals with the measurement, monitoring, display etc. of the several of energy exchanges which take place during process operations. “In short Instrumentation is the study of Instrument.”

Instrument:

Instrument is a device which is used to measure, monitor, display etc. of a process variable.

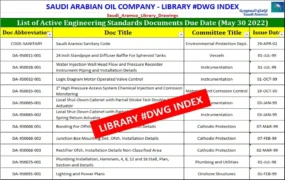

Some Saudi Aramco Standards (SAES):

1- SAES – J-001 (Instrument Index)

2- SAES – J-002 (Regulated Vendor List for Instrument/Technically Acceptable Instrument)

3- SAES – J-003 (Basic Design Criteria)

4- SAES – J-004 (Instrument Symbol and Identification)

5- SAES – J-005 (Drawing and Forms)

6- SAES – J-100 (Flow Measurement)

7- SAES – J-200 (Pressure Measurement)

8- SAES – J-300 (Level Measurement)

9- SAES – J-400 (Temperature Measurement)

10- SAES – J-502 (Analyzer Shelter)

11- SAES – J-505 (Combustible Gas and Hydrogen Sulfide in Air Detection System).

12- SAES – J-600 (Pressure Relief Valve)

13- SEAS – J-601 (Emergency Shutdown and Isolation Systems)

14- SAES – J-700 (Control Valve)

15- SAES – J-801 (Control Building)

16- SAES – J-901 (Instrument Air Supply System)

17- SAES – J-902 (Electrical System for Instrumentation) – Cable tray Noise Susceptibility Levels (NSL)

18- SAES – J-903 (Intrinsically Safe System)

19- SAES – B-006 (Fire Proofing of Cable for Fire Hazardous Area)

20- SAES – B-068 (Electrical Area Classification)

21- SAES – P-104 (Wiring Methods and Materials)

22- SAES – P-111 (Grounding)

23- SAES – P-103 (UPS and DC System)

24- SAES – T-634 (Telecommunications – Cable Testing and Acceptance)

25- SAES – T-796 (Communications Facility Grounding Systems)

26- SAES – T-911 (Telecommunication Conduit System Design)

Various NEC article numbers:

250 Grounding and Bonding

300 Wiring Methods & Materials

320 Armored Cable

344 Rigid Metal Conduits

352 Rigid Nonmetallic Conduits

354 Nonmetallic Underground Conduits

358 High Density Polyethylene Conduits

360 Flexible Metallic Tubing

362 Electrical Nonmetallic Tubing (ENT)

366 Power and Tray Cable

392 Cable Tray

500/505 Hazardous Location

504 Intrinsically Safe System

700 Emergency System

727 Instrument Cable Tray

760 Fire Alarm System

Some Abbreviations:

QCP Quality Control Plan

ITP Inspection Test Plan

TQ Technical Query

SAEP Saudi Aramco Engineering Procedure

SAES Saudi Aramco Engineering Standard

SAIC Saudi Aramco Inspection Checklist

SATIP Saudi Aramco Typical Inspection Plan

SATR Saudi Aramco Test Report

SASD Saudi Aramco Standard Drawing

SAIP Saudi Aramco Inspection Personal

SAMSS Saudi Aramco Materials System Specification

SASO Saudi Arabian Standards Organization

AWC Armor Wire Cable

NEC National Electrical Code

NACE National American Corrosion Engineers

SCADA Supervisory Control and Data Equation

ANSI American National Standards Institute

ASTM American Society for Testing and Materials

ASME American Society of Mechanical Engineers

BS British Standards

IEEE Institute of Electrical and Electronic Engineers

ICEA Insulated Cable Engineers Associations

IEC International Electrotechnical Commission

NEMA National Electrical Manufactures Associations

NFPA National Fire Protection Association

ATEX Atmospheres Explosibles

FM Factory Mutual

IP Ingress Protection

UL Underwriters Laboratories

ITC Instrument Tray Cable

PLTC Power Limited Tray Cable

PVC Polyvinyl Chloride

XLPE Cross Linked Polyethylene

XLPO Cross Linked Polyolefin

HDP High Density Polyethylene

RTD Resistance Temperature Detector

SWA Still Wire Armored

MICC Mineral Insulation Copper Conductor

PILC Paper Insulation Copper Conductor

FOC Fiber Optical Cable

OTDR Optical Time Domain Reflectometer

RTA Request for Technical Approval

MTC Material Test Certificate

Color Code:

AC Supply: Phase Black

Neutral White

Ground Green or Green with yellow tracer

DC Supply: Positive Red

Negative Black

Signal Pair: Positive Black

Negative White

Signal Tried: Positive Black

Negative White

Third Wire Red

Thermocouple: Positive as per ANSI MC 96.1 (Yellow)

Negative as per ANSI MC 96.1 (Red)

Instrumentation Question And Answer

1. What is QA/QC?

Ans: QA/QC means, “Quality Assurance / Quality Control” The purpose of this (QA/QC) is to establish the sequence of requirement for the quality of material, quality of works, its inspection, and records.

2. What is the MMG Quality Control Management System?

Ans: ISO 9001 ~ 2000

3. What is the Quality Control?

Ans: Quality Control “Those activities and techniques used to achieve and maintain the quality of product, process or service”.

4. What is Quality Control Plan?

Ans: Quality Plan “Document Specification which procedures and associated resources shall be applied by whom and when to specific project, product, process or contract”.

5. What is non-conformity?

Ans: Non-conformity “Non-fulfillment of requirement”. (Complete failure of a system, or controls, which result in completely unsatisfactory goods or services being provided).

6. What is the Specification?

Ans: Governing Document Acceptance Criteria.

7. Who are the responsible for Quality?

Ans: Everybody within all organization.

8. What is the basic responsibility of a QA/QC personal?

Ans: To ensure execution of works and comply fully as per standard and approved specs.

9. What is the basic required document for a QA/QC personal?

Ans: The basic required documents for a QA/QC personal are as following.

ITP (Inspection Test Plan): To conduct the quality check (Inspection of Witness, Surveillance and Hold Point) etc.

RFI: To conduct the inspection of completed work.

QR (Quality Record): To maintain the quality records of completed works etc.

NCR: To issue warning in case of serious violation of standard.

WP (Work Procedure): Standard procedure to execute the works.

P & ID: As a reference to ensure that the work is as per standard drawing.

MTC: To ensure that material comply the PES standard specs.

Calibration Report: To ensure parameters are function checked as per IDS.

PP (Project Plan): To ensure that the instruments are installation as per P & ID and PP as per convenience.

Hook-up: To ensure that the remote connection of pneumatic is done correctly.

Wiring Diagrams: To ensure that wiring is done correctly

ILD: To ensure that the sequential wiring is done correctly.

IDS/ISS: To ensure that the instruments comply with the basic requirement.

QCO: To issue a warning in case of little violation and observation.

DR: Discrepancy Report.

10. What are QA/QC’s ITP and QCP? Give brief?

Ans: ITP: This procedure informs about the kinds of quality check (surveillance, inspection, witness or hold pints) means quality of works is being done in proper sequences.

QCP: This procedure addresses the activities and requirement in details

Dear

Good day