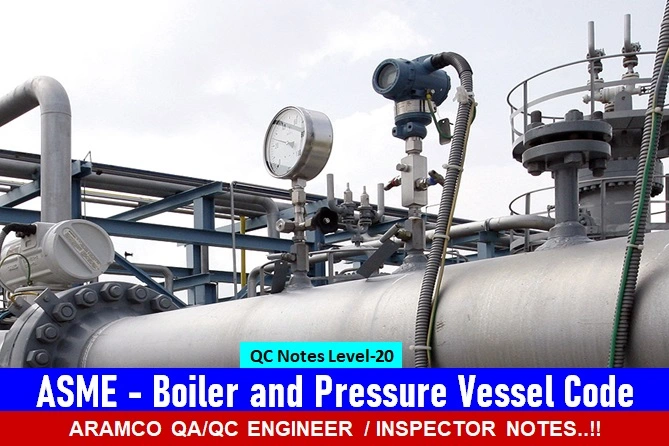

QC Notes Level-20

ASME BOILER AND PRESSURE VESSEL CODE

- SECTION I – POWER BOILERS.

- SECTION II – MATERIALS.

- SECTION III – NUCLEAR POWER PLANT COMPONENTS.

- SECTION IV – HEATING BOILERS.

- SECTION V – NONDESTRUCTIVE EXAMINATION.

- SECTION VI – RECOMMENDED RULES FOR CARE AND OPERATION OF HEATING BOILERS.

- SECTION VII – RECOMMENDED RULES FOR CARE OF POWER BOILERS.

- SECTION VIII – PRESSURE VESSELS ( DIV 1, DIV 2, DIV 3 ).

- SECTION IX – WELDING AND BRAZING QUALIFICATION.

- SECTION X – FIBER GLASS REINFORCED PLASTIC PRESSURE VESSEL.

- SECTION XI – RULES FOR IN-SERVICE INSPECTION OF NUCLEAR POWER PLANT COMPONENTS

Out of above ASME sections ASME SECTION VIII Code will be used for Pressure Vessels. in this sections there are three divisions. this code used in combination of Section II for materials, Section V for NDT Testing and Section IX for Welding and Brazing qualifications.

lets see short Summary of ASME SECTION VIII DIVISION 1, DIVISION 2 And DIVISION 3.

- ASME SECTION VIII DIVISION 1 – Unfired Pressure Vessels Rules.

- ASME SECTION VIII DIVISION 2 – Alternative Rules for Pressure Vessels.

- ASME SECTION VIII DIVISION 3 – Alternative Rules for High Pressure.

Commonly used Material for Construction of Pressure Vessels:

In fabrication of pressure vessel Steel,Cast iron and Aluminum material are used most commonly but out of this Steels are most widely used for pressure vessel fabrication so , from group of Steel Carbon steel , Alloy steel , Stainless steel are used.

Material Selection guideline for Pressure vessels:

While selecting the Material of construction of pressure vessels Temperature is most important factor to be considered. so, lets see some materials suitable for various types of Temperature Service.

- Low-Temperature Service – Carbon steel, 3 1/2 Nickel, 2 1/2 Nickel.

- Intermediate Temperature Service – Carbon steel.

- High-Temperature Service – C-1/2 MO, 1 Cr-1/2 MO,2 1/4 Cr -1 MO, Stainless Steel, Incoloy, Inconel.

- Cryogenic Service – Stainless steel, 9 Nickel.

- This is all about basics o pressure vessels.

Continue QC Notes Level-21 ⭕ Saudi aramco welding standards

See More: Aramco Quality Standard

- Index SAES | Excel | Saudi Aramco Engineering Standards

- Aramco :: Pressure Vessel Reference, Installation Standards

- ARAMCO :: COMPUTER BASED TESTING (CBT)

- PUMP SKID DESIGN

- pump sizing calculator excel

- Centrifugal Pumps and Compressors Installation Standards

- Saudi Aramco form 175 inspection & testing requirement

- HAZOP Vs HAZID in the Oil & Gas Industry

- OIL & GAS PROJECTS CODES & STANDARDS