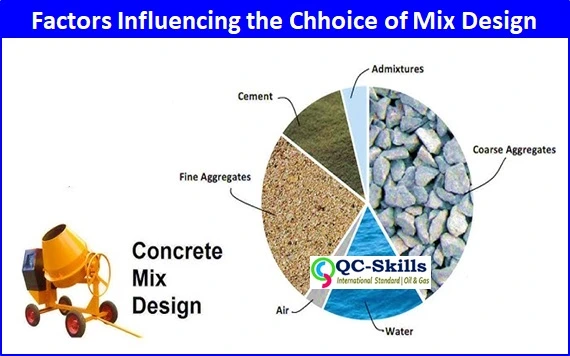

To produce concrete of required strength and properties, selection of ingredients and their quantity is to be found which is called concrete mix design.

Proper mix design will solve every problem arises in concrete while placing or curing etc.

The mix design also helps to produce economical concrete. Generally, cement is more costly than other ingredients of concrete. So, quantity and quality of cement is designed by proper mix design concept.

Concrete mix design concept is majorly depending upon the following:

- Strength and durability

- Workability

- Economy

- specifications

Procedure(step by step process):

1.Calculation of target strength of concrete

2.Selection of water-cement ratio

3.Determination of aggregate air content

4.Selection of water content for concrete

5.Selection of cement content for concrete

6.Calculation of aggregate ratio

7.Calculation of aggregate content for concrete

8.Trial mixes for testing concrete mix design strength

Target strength is denoted by f(t) which is obtained by characteristic compressive strength of concrete at 28 days (fck) and value of standard deviation (s):

- f(t) = fck + 1.65 s

- S(M30-60) = 5

- standard deviation table in IS456.

Check (steps):

1) Specific gravity of cement, fine aggregates, course aggregate and water absorption of CA and FA

2) Weather condition -Mild, severe, extreme conditions.

3) check table for max water/cement ratio for different grade of concrete in IS456 for different weather conditions.

4)then check table for water content for different aggregate size , ex for 20mm- 186kg water is used.

5) then cement content can be find by cement content= water/cement ratio

6) then check aggregate proportion table for different aggregate size.

and final step for mix calculations