Structural & Mechanical Equipment Inspection

Aramco QC Notes Level-9

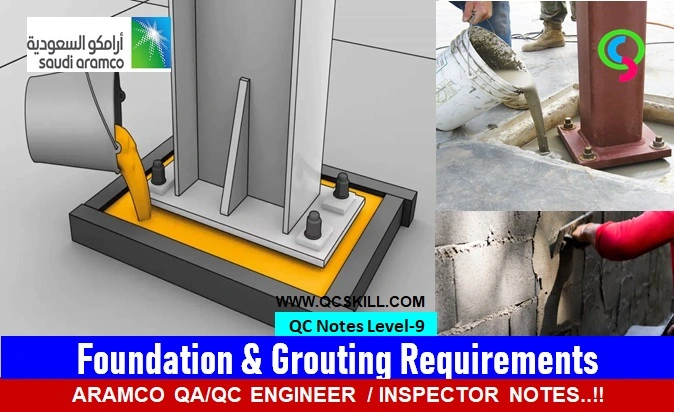

Foundation General Information

Grouting Reference Standard

Pre-Grout Meeting

Grouting of Foundation General Information

Foundation & Grouting Requirements

FOUNDATION GENERAL INFORMATION

- Top of Concrete Foundation shall have a minimum of 150mm above finish grade. (not applicable to instrument stand pipe, or pedestal inside the building not subjected to wash-down water).

- Curing period of concrete foundation should be not less than 7 days after placement or until the compressive strength has reach 70% of the specified strength.

- All column base plate has a minimum of 4 anchor bolts.

- Installed padding plate with 25mm minimum elevation from top of the foundation and level the foundation plate using magnetic leveling or precision leveling.

- Leveling shims are installed with a maximum top elevation of 25mm from the top of concrete elevation.

- Top of the concrete has been roughened or chipped with hammer to remove laitance, oilsoaked or damaged concrete to the level of sound concrete or to a minimum of 1inch (25mm) from the top of the concrete.

- Top of the bearing surface and the bottom plate should be clean thoroughly.

- Variation in dimension between the centers of any two anchor bolts within an anchor bolt group shall be equal to or less than 1/8” (3mm) AISC Code of standard Practice for Steel Building and Bridges.

- Variation in elevation of the tops of anchor rods shall be equal to or less than ±13mm AISC Code of Standard Practice for Steel Building and Bridges.

- Installed the sole plate with ±1mm tolerance.

- Check the dimension of the anchor bolts and the bolt hole of the equipment, anchor bolts subject to vibration should be provided with additional nut to serve as locknut.

GROUTING REFERENCE STANDARD

- SATIP-Q-011-01 Epoxy Grout for Machinery Support

- SATIP-Q-010-01 Cement Based Non-Shrink Grouting

- 09-SAMSS-088 Aggregates for Concrete

- SAES-Q-005 Concrete Foundations

- SAES-Q-010 Cement Based, Non-Shrink Grout for Structural…

- SAES-Q-011 Epoxy Grout for Machinery Support

PRE-GROUT MEETING

- A pre-grout meeting should be held at least one day prior to the grout pour to understand and agree on procedures to ensure all necessary materials are on hand and to clarify grouting responsibilities. The party present in this meeting should include as a minimum, the grout manufacturing technical representative, the foreman in charge

of the grouting activities, the grouting materials coordinator and the safety representative. A representative from grout manufacturer is recommended if the installation personnel are not familiar with the grouting materials, forming, installation, and so forth or if a special purpose equipment train is being installed.

GROUTING OF FOUNDATION GENERAL INFORMATION

- Before grouting see to it that the foundation is clean, dry and oil free

- Soak/Moisten the surface with water at least 24 hours (NSCG)

- Start grouting from one side going to the other side to prevent air entrapment.

- Do not vibrate the grout as a means of helping it flow as this tends to separate the aggregate from the resin binder.

- Violent ramming of the grout is not permitted.

- Limited use of push tools maybe employed to help distributed the grout using long stroke rather than short stroke jabs.

- Air bubbles rising to the surface maybe remove by lightly spraying the bubbles surface with the grout manufacturing solvent cleaner.

- Remove any grout head boxes after the grout has set sufficiently.

- Foundation should be protected by burlap and polyethylene sheet to prevent from contamination

- Grout formworks shall be constructed with adequate strength.

- Concrete foundation should be cured for a minimum of 7 days or 70% of the concrete compressive strength.

- Grout minimum thickness is 25mm

- Temperature of grout when placed shall 23ºC ±3

- Compressive strength should be 35 MPa (5000 psi) minimum at 28 days

- Compressive strength should be 24.5 MPa (3500 psi) minimum at 7 days

- When grout water/cement ratio is 0.4 or less the grout shall be given a continuous water cure (cover with wet burlap and 0.15mm polyethylene) for minimum of 7 days

- Grout shall be tooled/chamfer to a 45º angle down from the bottom of the base plate after placement but before it sets up hard

- Total dissolved solids in water shall not exceed 500ppm

- pH shall be between 6-8

- Epoxy grout temperature 30C to 32C and no need of soaking

Continue QC Notes Level-10 ⭕ Structural Steel – SATIP-M-001-01 (Bolt Joint)

See More: Aramco Quality Standard