Power Transformer – Erection, Commissioning, Operation, & Maintenance Manual

- Introduction

A power transformer is a critical component in electrical power systems, designed to transfer electrical energy between circuits through electromagnetic induction. To ensure its proper functioning, it is essential to follow a structured approach for erection, commissioning, operation, and maintenance. This manual outlines the detailed procedures and best practices for each phase to ensure the longevity, reliability, and safety of the power transformer.

- Erection of Power Transformer

The erection phase involves the assembly, installation, and preparation of the power transformer at its designated location. This process is crucial to ensure the stability and safety of the transformer. The key steps include:

2.1 Site Preparation

Select a location that is free from flooding risk and has adequate ventilation.

Construct a foundation that can bear the weight of the transformer and is levelled to prevent vibrations.

Install grounding systems to ensure proper earthing of the transformer for safety.

2.2 Assembly and Installation

Transport the transformer to the site using a specialized vehicle.

Inspect the transformer for any physical damage during transportation.

Install the transformer on the foundation using lifting equipment like cranes.

Assemble the radiators, bushings, conservator tanks, and other auxiliary components.

Tighten all nuts, bolts, and fittings as per the manufacturer’s torque specifications.

Connect all cables, control wiring, and accessories as per the electrical drawings.

2.3 Oil Filling and Testing

Check the transformer’s oil for moisture content and dielectric strength before filling.

Fill the transformer with oil under vacuum to remove trapped air and moisture.

Perform tests like pressure tests on the tank and vacuum holding tests to ensure there are no leaks.

- Commissioning of Power Transformer

Commissioning is the process of validating the installation and preparing the transformer for its first operation. This phase ensures that all systems are functioning correctly and that the transformer is ready to be energized. The major steps include:

3.1 Pre-Commissioning Tests

Insulation Resistance Test (IR Test): Measures the insulation resistance of windings to ensure no insulation degradation.

Turns Ratio Test: Verifies the ratio of turns between the primary and secondary windings to ensure the correct voltage ratio.

Dielectric Tests: Tests such as the power frequency withstand test and lightning impulse test to verify the dielectric strength of the transformer.

Bushing Tests: Verify the integrity of bushings by measuring capacitance and tan delta.

3.2 Functional Checks

Verify the operation of protective relays, alarms, and trip circuits.

Check the cooling system, including the operation of fans and oil pumps.

Test the control and auxiliary circuits for correct operation.

3.3 Energizing the Transformer

Record all pre-energization readings, including temperature, oil level, and tap changer position.

Gradually energize the transformer by applying the voltage in steps.

Monitor for any abnormal sounds, vibrations, or heating.

Perform a load test to verify the performance of the transformer under rated conditions.

- Operation of Power Transformer

Operation refers to the day-to-day management of the transformer to ensure its safe and efficient performance. This involves routine monitoring, recording key parameters, and following safe practices.

4.1 Daily Monitoring

Temperature Monitoring: Regularly check oil and winding temperatures using temperature gauges.

Oil Levels: Ensure the oil level in the conservator tank is within the permissible range.

Load Monitoring: Monitor the load on the transformer and ensure it operates within rated capacity.

Noise and Vibration Checks: Pay attention to any unusual noise or vibrations that may indicate internal issues.

4.2 Operational Checks

Tap Changer Operation: Regularly change tap positions as per the load variations to maintain voltage levels.

Cooling System: Verify the operation of fans, radiators, and oil pumps.

Pressure Relief Device: Inspect the pressure relief device and ensure it operates properly during any pressure surge.

- Maintenance of Power Transformer

Regular maintenance is essential for prolonging the life of the transformer and preventing sudden failures. Maintenance activities are divided into routine and preventive maintenance.

5.1 Routine Maintenance

Oil Sampling and Analysis: Periodically analyze transformer oil for dissolved gas, moisture, and dielectric strength to detect early signs of issues.

Bushing Cleaning: Clean the bushings to avoid contamination and ensure proper insulation.

Tightness Check: Inspect and tighten all bolts, cable connections, and fittings.

Cooling System Inspection: Clean radiators and verify the functionality of cooling fans and oil pumps.

5.2 Preventive Maintenance

Insulation Resistance Test: Periodic insulation tests to monitor insulation condition over time.

Tan Delta and Capacitance Measurement: Measures the dielectric losses in insulation, helping identify aging or moisture presence.

Thermographic Inspection: Use infrared thermography to detect hot spots in the transformer and connected cables.

Breather Maintenance: Check silica gel in the breather and replace it when it becomes saturated with moisture.

5.3 Condition-Based Maintenance

Dissolved Gas Analysis (DGA): Monitor the levels of gases dissolved in the oil, such as hydrogen, acetylene, and methane, which indicate internal arcing or insulation breakdown.

Partial Discharge Monitoring: Use specialized equipment to detect partial discharges inside the transformer, which can indicate insulation defects.

- Safety Precautions

Always de-energize the transformer and follow lockout-tagout procedures before performing any maintenance.

Wear appropriate personal protective equipment (PPE) such as gloves, helmets, and safety glasses.

Follow the manufacturer’s instructions and comply with local regulations and safety standards.

- Troubleshooting Common Issues

Overheating: Inspect the cooling system, check for blocked radiators, and ensure proper ventilation.

Noise: Unusual noise can indicate internal faults like loose core lamination or winding defects.

Oil Leakage: Identify the source of the leak and repair it using suitable sealing compounds.

Low Insulation Resistance: Investigate potential moisture ingress or contamination in oil.

- Documentation and Reporting

Maintain a log of all tests, inspections, and maintenance activities. Proper documentation helps in identifying trends in transformer behavior and ensures compliance with standards.

- Conclusion

Proper erection, commissioning, operation, and maintenance are critical to ensuring the reliability and efficient functioning of a power transformer. Adhering to these guidelines helps extend the transformer’s life, ensures safe operations, and minimizes the risk of unexpected failures. Always follow the manufacturer’s instructions and consult with experts when dealing with complex issues.

This manual provides a comprehensive approach to managing power transformers, aimed at both technicians and engineers working in the field. It is recommended to update the manual periodically to incorporate new standards and technologies.

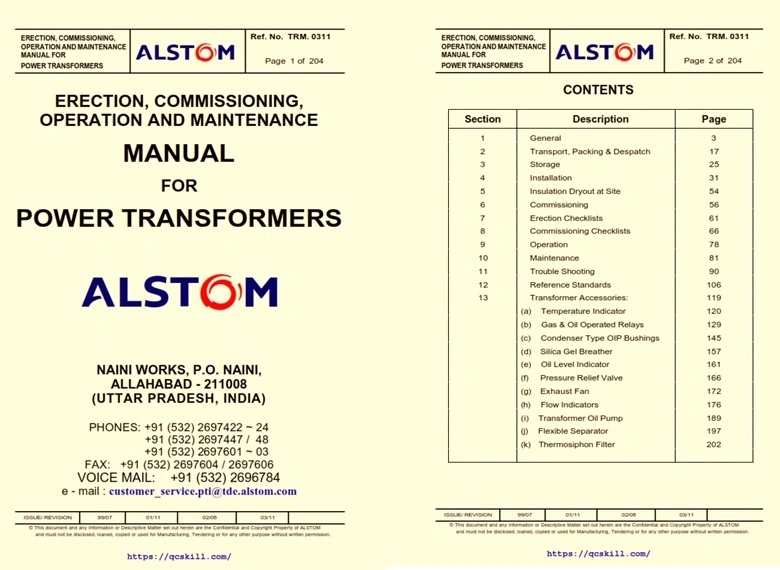

Download PDF – Alstom-Erection & Commissioning Operation and Maintenance Manual for Power Transformer

Title : Power Transformer – Erection, Commissioning, Operation, & Maintenance Manual

Type : Microsoft Excel Spreadsheet (xlsx)

Size : 3999.0 KB