Roles and Responsibilities of Mechanical QC Inspector (Schedule Q’ Requirements Saudi Aramco/Neom)

If you want to work in Aramco Projects or Neom Projects you have a rich experience in Mechanical and you have to fullfill the Schedule Q requirements which states for QCIs ” Inspector shall be minimum a vocational diploma level or equivalent; shall be able to read, write and speak English Language; shall be fully conversant with applicable Industry Standards and Specifications; and shall perform a variety of inspection functions with minimal supervision. Personnel employed by the CONTRACTOR or its subcontractors to perform the work described in the Contract, as a minimum shall meet the following years of relevant experience: a total of (7) years of inspection experience for a senior inspector and min (3) years of inspection experience for an inspector. Inspector(s) responsible for Non-destructive testing (NDE) qualified in accordance with the requirements specified in ASNT SNT-TC-1A, ISO 9712 or EN 473 Level II as a minimum. Inspector(s) responsible for inspection of painting and coating activities shall be certified by SSPC or NACE,BGAS or equivalent. Inspector responsible for inspection of metal welding shall be a Certified Welding Inspector CSWIP 3.1″

A Mechanical Quality Control Inspector’s responsibilities are diverse and encompass a broad range of activities aimed at ensuring the reliability, functionality, and compliance of mechanical systems within a project, contributing significantly to the overall quality of the construction or engineering endeavor.

A Mechanical Quality Control Inspector in the construction field is covering HVAC, Rotatory, Static, and Plumbing works plays a pivotal role in ensuring the quality and compliance of mechanical systems as per the scope of the project. Duties and responsibilities depend on the company’s organizational structure and the project type.

1) Quality Assurance Compliance ✅

Oversee compliance with project specifications, codes, standards, and regulations related to HVAC, Rotatory, Static, and Plumbing systems and other related activities as per the scope of the project.

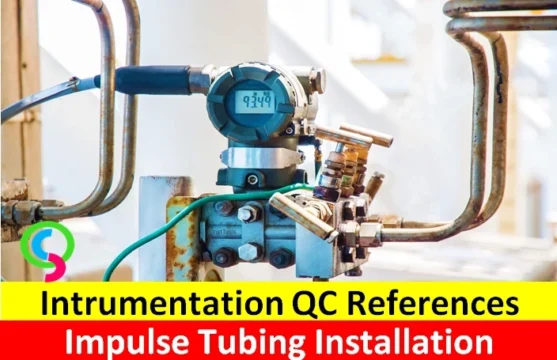

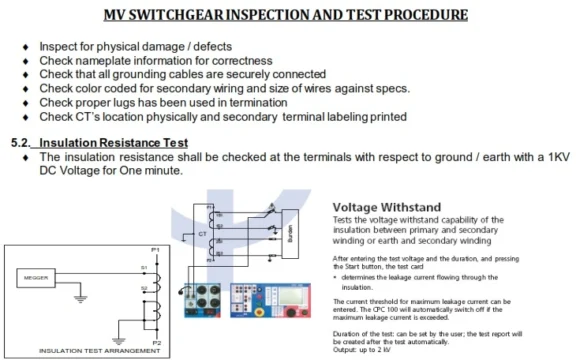

2) Inspection and Testing ✅

Conduct thorough inspections, including visual assessments, measurements, and functional tests, to ensure proper installation, alignment, and functionality of mechanical equipment and systems as per the approved ITP/SATIP.

3) Documentation and Reporting ✅

Maintain detailed records of inspections as per WIR (Work inspection Reports) RFI (Request for Inspection), tests, and non-conformities. Generate reports highlighting findings, deviations, and corrective actions taken or required.

4) Quality Audits and Reviews ✅

Participate in quality audits and reviews, ensuring that mechanical systems meet established quality standards and requirements depends on the project progress or as per PQP (Project Quality Plan).

5) Collaboration and Coordination ✅

Collaborate with project managers, engineers, contractors, and subcontractors to address quality-related issues, provide guidance, and ensure alignment with project plans.

6) Risk Assessment and Mitigation ✅

Identify potential risks or deficiencies in mechanical systems, propose risk mitigation strategies, and contribute to risk assessment processes.

7) Material and Equipment Inspection ✅

Inspect materials, components, and equipment for compliance with project specifications and quality standards before installation. (Skids, piping, valves, motor pumps etc)

8) Training and Compliance Enforcement ✅

Provide guidance and training to contractors and subcontractors on quality control standards and procedures. Enforce compliance with established quality control processes.